Fragtfri levering i Europa

|

5 års garanti

|

FSC®-certificeret

Fragtfri levering i Europa

5 års garanti

FSC®-certificeret

Vi har arbejdet med bæredygtighed siden den dag, vi stiftede Form & Refine. Begrebet bæredygtighed har formet vores virksomhedskultur, og alt, hvad vi gør, hviler på et bæredygtigt værdigrundlag. Vi tror på, at vi gennem bæredygtige metoder kan bevare og forbedre vores miljø ved at understøtte kulturer og enkeltpersoner, der arbejder med bæredygtigt håndværk.

Vi forpligter os til fortsat at styrke vores egen og vores medarbejderes og samarbejdspartneres bevidsthed om, hvordan vores handlinger påvirker naturen. At gøre verden til et bedre sted vha. bæredygtighed er en integreret del af vores daglige praksis, fordi vi ønsker at bringe fremtidige generationers muligheder de bedste forudsætninger.

Vi stræber altid efter at lære af og bygge videre på vores erfaringer og anlægge nye og spændende perspektiver på bæredygtighed.

Form & Refine er en FSC-certificeret virksomhed. FSC (Forest Stewardship Council) er en international non-profit medlemsorganisation, der er dedikeret til at fremme ansvarligforvaltning af verdens skove. Vi bestræber os på kun at anvende FSC-certificeret træ i vores kollektion. Det er et naturligt valg at samarbejde med FSC, da vi primært tilbyder moderne træmøbler skabt med en miljøbevidst designfilosofi.

Vores fokus på begrebet bæredygtighed er på linje med FN’s Verdensmål for Bæredygtig Udvikling (UNGG). Verdensmålene beskriver en bred vifte af globale problemstillinger og målsætninger, som stemmer overens med vores virksomheds værdigrundlag. Vi har opdelt vores bæredygtighedsløfter i følgende fem kategorier: CO2-aftryk, Holdbarhed, Social lighed, Økonomiske fordele og Naturmaterialer. Man kan dykke ned i vores fem bæredygtighedsløfter her:

Vi forpligter os til at minimere vores CO2-aftryk ved at bruge lokale materialer og værksteder for at øge vores bæredygtighed i virksomheden. Vi har som mål, at alle vores materialer skal skaffes og forarbejdes inden for en radius af 100 km.

Vi fremstiller alle vores møbler og trævarer i Europa. Vi benytter kun træ, der er fældet inden for kort afstand fra vores værksteder. Derfor bruger vi ikke teak eller mangotræ fra Sydamerika og Asien eller egetræ fra Nordamerika. Denne beslutning er med til at reducere vores CO2-aftryk betragteligt og er miljømæssig bæredygtighed.

Derudover transporterer vi alle vores materialer med skib eller lastbil og undgår flytransport.

Træer optager og lagrer store mængder kuldioxid (CO2). Når et træ fældes, er det vigtigt, at den CO2, det rummer, ikke udledes i atmosfæren igen. Derfor undgår vi at brænde træ på vores værksteder.

Medejere af Damsbo Skov

Vi er stolte af at være medejere af den privatejede Damsbo Skov på Fyn. Dette medejerskab har givet os indsigt i, hvor krævende god skovdrift er, og at bæredygtige metoder er den eneste måde at bevare en skov på over længere tid. Skovens sociale og miljømæssige værdi påvirker de valg, vi træffer hver eneste dag. Når der fældes et træ, skal der plantes mindst 200 nye træer for at sikre, at der står mindst ét 140 år gammelt førsteklasses egetræ til kommende generationer.

Vores mål:

Vores mål er, at alle vores materialer skal skaffes og forarbejdes inden for en maksimal radius af 100 km.

Vi vil skabe produkter, der er lavet til at holde, takket være deres økologiske kvalitet og tidløse design.

Vi er stolte af vores slow living-praksis, hvor vi hvert år producerer små serier af kvalitetsprodukter med fokus på bæredygtighed, frem for at fokusere på kvantitet og på at lancere nye produkter så tit som muligt. Det udvikler en kultur, som repræsenterer det diametralt modsatte af brug og smid væk-samfundet. Vi ønsker at hjælpe verden mod et mere bæredygtigt forbrug, for de fremtidige generationer.

– Vi løber ikke efter mode og trends.

– Vi skaber ting, der kan holde livet ud og være til glæde for kommende generationer.

– Vi stræber efter at skabe produkter, der har potentialet til at blive designklassikere.

Garanti

– Vi giver fem års garanti på hele vores kollektion.

– Vi skaber produkter, der kan holde, takket være deres økologiske kvalitet og tidløse design.

Reklamations- og returrate

– Vores reklamationsrate er 0,7 % – bedre end de fleste interiørproducenter.

– En lav reklamationsrate betyder langt mindre miljøbelastning, fordi det indebærer, at der ikke skal fremstilles så mange produkter.

– Vores returrate er 0,2 %. Sidste år fik vi kun 14 ordrer retur. Det er enormt tilfredsstillende for os, at slutbrugerne af vores produkter er tilfredse med vores produktdesign og materialekvalitet.

De sociale effekter af produktion overses tit. Vi prioriterer en praksis, der fremmer social ligeværdighed og understøtter de etiske aspekter af bæredygtighed. Blandt andet gør vi en konkret indsats for at beskytte og respektere oprindelige folks rettigheder og bevare traditionelle håndværk. Vi tager medarbejdertrivsel og menneskerettigheder meget alvorligt.

Vi samarbejder med sociale værksteder, kooperativer og små familievirksomheder med tradition for godt håndværk.

Her er en oversigt over, hvem vi samarbejder med, og hvorfor:

Al vores alpakauld kommer fra et kooperativ af 400 lokale bønder i Andes-regionen i Bolivia. Området er det naturlige levested for alpakaen, som spiller en helt central rolle i den oprindelige befolknings liv, hvilket er en del af bæredygtigt landbrug. Den familieejede systue, som vi primært arbejder med, benytter traditionelle håndværksmetoder til at bearbejde de luksuriøse fibre fra disse godmodige dyr til tekstil. Tekstilarbejdet er den væsentligste indtægtskilde for den oprindelige befolkning.

– Alle Shoemaker Chairs™ kommer fra en af de sidste og ældste familieejede og drevne trædrejervirksomheder i Danmark. Vi gør en indsats for at fremme håndværk som bæredygtigt erhverv.

– Alle keramiske produkter kommer fra et lokalt pottemagerværksted i Portugal med en historie, der går helt tilbage til 1800-tallet.

– Alle glasvarer kommer fra en lokal familieejet fabrik i Portugal, som er en af de sidste tilbageværende producenter af håndlavet glas i landet.

– Alle A Line produkter kommer fra et familieejet snedkerværksted i bjergbyen Jajce i det centrale Bosnien Hercegovina.

– Vi samarbejder med det sociale værksted HKI (Hans Knudsen Instituttet) i København. HKI støtter mennesker, der af forskellige grunde har svært ved at indgå på det danske arbejdsmarked.

– Vi arbejder med en af de sidste tilbageværende glasproducenter, der anvender de traditionelle portugisiske mundblæsningsteknikker. Vi arbejder for at ære de gamle teknikker og det håndværk, der er skabt.

Mål:

– Vi vil fortsat arbejde med mere socialt indstillede værksteder og undersøge nye måder at skabe et socialt aftryk, som afspejler bæredygtighed.

Vi stræber efter at skabe en succesrig og profitabel virksomhed med en bæredygtig udvikling uden at gøre skade på jorden. Derigennem ønsker vi at bruge vores brand til at gøre en positiv forskel ved at promovere vores agenda for bæredygtighed.

Vi vil gerne have forbrugerne til at vælge vores produkter frem for mindre bæredygtige produkter.

I al enkelhed håber vi, at vi kan gøre så stor en forskel, at forbrugerne betragter produkter, som vores, som en forudsætning for at bevare naturen og skabe en bæredygtig udvikling. Det er vi overbeviste om, at vi kan opnå ved at tilbyde bæredygtige kvalitetsprodukter til konkurrencedygtige priser. Det skal være drivkraften for økonomisk udvikling hos os.

Naturmaterialer medfører langt mindre miljøbelastning i form af CO2 -udslip end andre materialer. Naturmaterialerne er derfor essentielle for vores agenda for bæredygtighed.

Vi anvender kun de mest holdbare og bæredygtige materialer fra jordens ressourcer som f.eks. træ, messing, stentøj, stål, alpaka, kork og vegetabilsk garvet læder. Mange af disse materialer bliver kun smukkere med tiden og giver vores produkter en lang levetid.

Hvad vi ikke gør eller bruger

Vi bruger ikke aluminium

Aluminium har en lang række negative konsekvenser for miljøet og kræver store mængder energi at fremstille, hvilket ikke er til gavn for bæredygtighedsbegrebet. Det kræver 211 gigajoule per ton at fremstille aluminium, sammenlignet med 22,7 gigajoule per ton for stål eller messing. Det vil sige, at stålproduktion kræver 90 % mindre energi end aluminium.

Aluminium udleder derfor en del mere forurening og skader vores miljø. Det er en af de mange grunde til, at vi udelukkende benytter stål eller messing.

Vi vil gerne bruge 100 % genbrugt aluminium, når det en dag bliver muligt.

Vi bruger ikke almindelig plastik i vores produkter, kun rPET (genbrugs PET)

Vi bruger ikke almindelig plastik i vores møbler, idet plastik stammer fra olieproduktion, ofte fracking (hydraulisk frakturering), som er en voldsomt miljøskadelig proces. PET er en af de få plasttyper, der kan genbruges, da det består af få og enkle ingredienser uden giftstoffer. Det genbrugsmateriale kaldes rPET som står for ”recycled PET”. Vi bruger rPET i de produkter, hvor dets egenskaber giver mening og er svære at erstatte af andet, som f.eks. dele af vores emballage og pudefyld til vores inderpuder.

Vi bruger ikke kemikalier eller giftstoffer – vi ønsker bæredygtighed

Giftstoffer og kemikalier kan skade mennesker, dyreliv og miljø på mange forskellige måder, uanset om de ender i jorden, i vandløb eller i luften. Nogle giftstoffer, f.eks. kviksølv og bly, bliver i miljøet i årevis og ophobes over tid.

Bæredygtighed som emballage

Vi bruger overvejende genbrugspap som emballage, enten almindeligt genbrugspap eller genbrugscellepap.

Vi har som mål kun at bruge papirtape og bruger findelt genbrugspap som kassefyld.

Det er vores mål at undgå plast i vores emballage og kun få i tilfælde bruge rPET. Det er en vanskelig udfordring, da vi samtidig er nødt til at finde lokale løsninger på problemet. For eksempel giver det ikke meget mening at transportere en god, bæredygtig emballageløsning fra Europa til Bolivia, fordi transporten i sig selv udgør en stor miljøbelastning. Det er vores mål, at al plastik, der anvendes i vores emballage, skal være rPET; en målsætning, der allerede er gennemført for hele vores produktkollektion for at opnå den bæredygtighed vi ønsker.

Vores mål:

– Vi har som mål at bruge plastfri emballage eller rPET-emballage inden 2025.

– Vi stræber efter, at alle vores trævarer (herunder emballage) skal komme fra certificerede kilder inden 2024.

– Vi har som målsætning at bruge flere upcyclede materialer eller genbrugsmaterialer, hvor det er muligt.

Læs mere om de materialer vi bruger:

Træ

Kvalitetstræ er Form & Refines hjerteblod, da det ubestrideligt er et af de mest bæredygtige materialer i verden og udgør en mindre miljøbelastning end noget andet materiale.

Træ er et bæredygtigt naturmateriale. Det har lang levetid, det kan genbruges og genanvendes, det optager kuldioxid, det holder godt på varmen, træaffald er 100 % bionedbrydeligt, og træ har en positiv effekt på vores fysiske og mentale helbred. Det er hvad bæredygtighed handler om.

Det meste af vores træ kommer fra certificerede skove, primært FSC-certificeret (Forest Stewardship Council). Træet, der anvendes til Shoemaker-produktionen, er PEFC-certificeret (Programme for the Endorsement of Forest Certification). Dette valg afspejler vores ønske om at forhindre skovrydning, bevare biodiversitet og samtidig beskytte menneskerettigheder.

Vi understreger, at vi kun bruger træ fra europæiske skove, som ligger tæt på de værksteder, hvor træet bearbejdes.

Vores mål:

– Vi stræber mod at købe alt træ til vores træmøbler fra certificerede skove inden 2025.

Alpaka

Alpakafibre er miljøvenlige og bevarer deres naturlige karakter, når de bearbejdes. Vores alpakauld udsættes ikke på noget tidspunkt for kemikalier eller giftstoffer. Form & Refines Aymara Alpaca kollektion er fremstillet af 100 % ren alpakafiber og er ikke blandet med syntetiske fibre eller andre materialer af ringere kvalitet.

Vi bruger stort set udelukkende alpakauldens naturlige nuancer og benytter kun et begrænset udvalg af miljøvenlige farvestoffer, som er godkendt til tøjproduktion på en bæredygtig måde.

Kork

Al vores kork kommer fra Portugal. Kork er et naturligt miljøvenligt materiale. Det er fuldt bionedbrydeligt og er let at genanvende, uden at der produceres giftigt restaffald.

Korkegens bark høstes hvert 9. til 12. år. Hver gang der høstes kork, dannes der ny bark, som dermed optager CO2. Korkege i Portugal alene optager 10 millioner tons kuldioxid om året. Samtidig producerer træerne store mængder ilt.

Kork og korkegeskove er en central kilde til beskæftigelse i landlige regioner og er med til at sikre overlevelsen ad lokalsamfund.

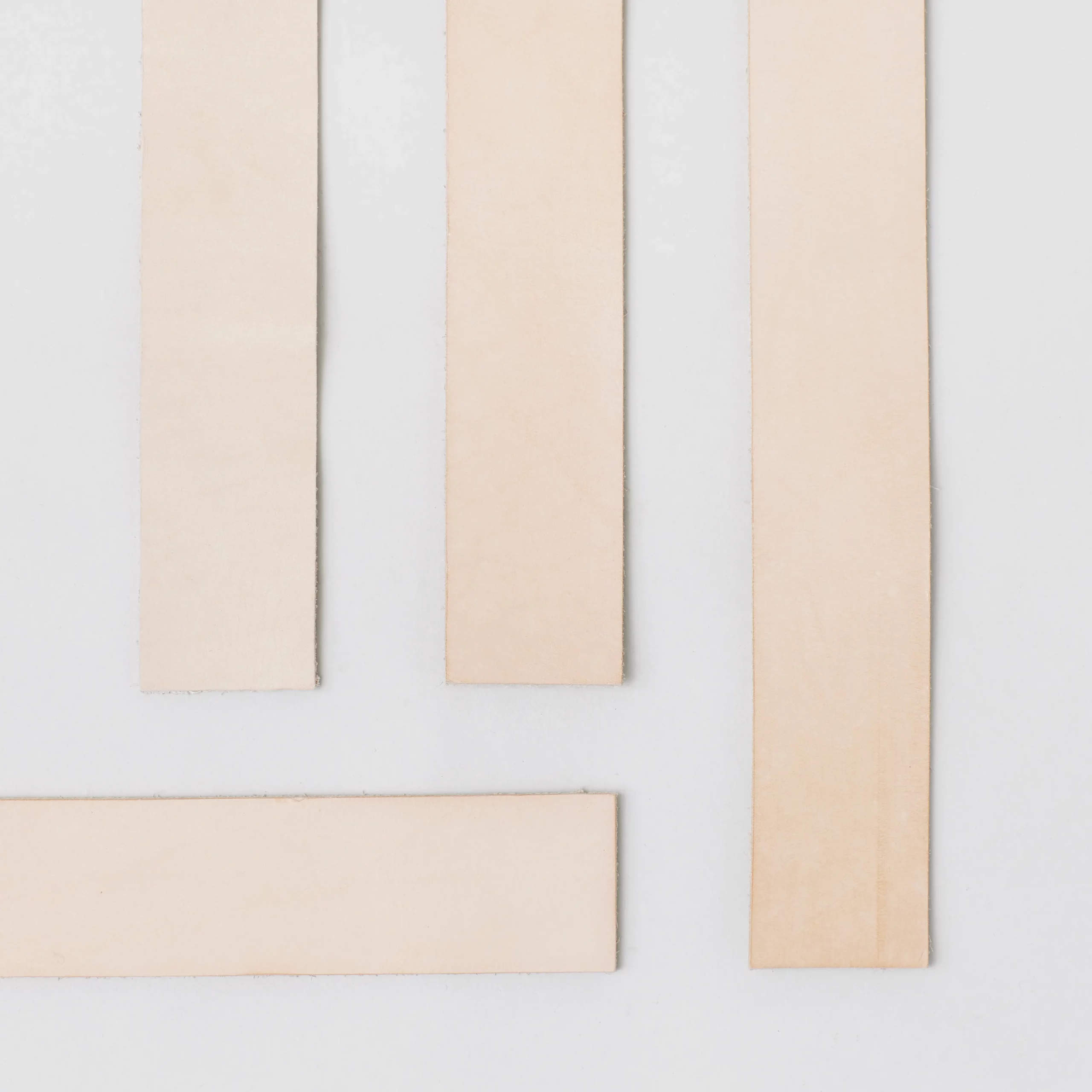

Vegetabilsk garvet læder

Vores læder fremstilles af oksehuder i Italien og Portugal. Vegetabilsk garvning er en traditionel måde at garve læder på, som har rødder helt tilbage til omkring 6.000 år før den moderne tidsregning. Vegetabilsk garvning er en organisk metode, hvor skindet præpares af naturlige garvestoffer i bark eller andre plantedele.

På grund af den omhyggelige garveproces og de naturlige garvestoffer udvikler vegetabilsk garvet læder med tiden en smuk og dyb patina. Det tykke og slidstærke læder har en lang levetid uden at revne eller tørre ud. Det har en behagelig og naturlig farvetone og duft. Alt vores vegetabilsk garvede læder er bionedbrydeligt.

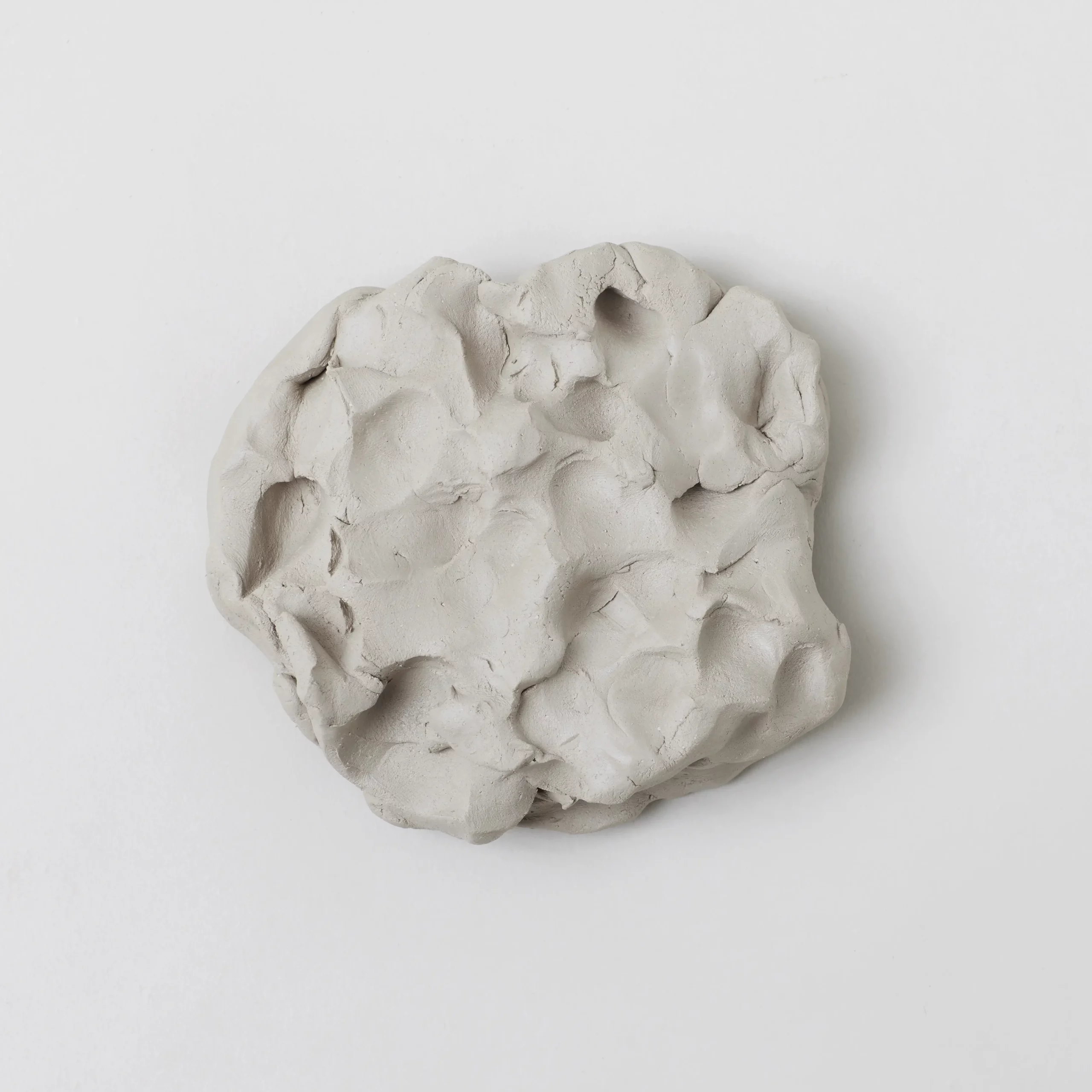

Stentøj

Vores stentøj fremstilles af portugisisk ler, som er et naturligt, plastisk materiale, der består af mineraler og vand. Mineralsk ler er naturligt forekommende i jorden og er et glimrende råmateriale til smukke, sikre og bæredygtige produkter.

Stentøj er et kompakt keramisk materiale, som brændes ved høje temperaturer for at gøre det tæt og vandafvisende. Det er fremstillet af ler og mere holdbart end andre typer af keramik eller lertøj.

Kvalitetsstentøj indeholder hverken bly eller giftstoffer, er sikkert at anvende til fødevarer og kan vare evigt, hvis man passer på det.

Emballageaffald

Genanvendeligt affald rummer et enormt potentiale for bæredygtig innovation. Et eksempel er Recomas Pack Wall Design Board, der fremstilles af kasserede juice- og mælkekartoner. Disse kartoner omdannes til en komposit bestående af pap, plast og aluminium – et fuldt genanvendeligt materiale, der ikke kræver adskillelse ved bortskaffelse. Det kan smeltes om og genbruges, hvilket understøtter en cirkulær produktionsproces.

Hvert år genanvender denne metode hele 7 millioner kg nordisk emballageaffald, hvilket forhindrer næsten 5.000 tons CO₂-udledning. Processen er samtidig kemikaliefri, uden brug af tilsætningsstoffer eller skovrydning – den benytter udelukkende kasserede kartoner og energi. Dette materiale er ikke blot en ressource, men en bæredygtig løsning, der forvandler affald til værdi.

En imponerende anvendelse af materialet ses hos Form & Refine’s Remake Stool, som elegant demonstrerer, hvordan innovativt design og bæredygtighed kan gå hånd i hånd.

Andedun til inderhynder

Vores inderhynder er fyldt med 50 % fiberkugler og 50 % andedun. Fiberkuglerne består af 100 % rPET og er fremstillet i Nordeuropa.

Vores andedun kommer fra et traditionelt drevet fjerkræbrug i Ungarn. Vi bruger ikke andedun fra levende dyr. Andedunene vaskes, tørres og er fuldstændig sterile.

MDF

MDF står for medium-density fibreboard (træfiberplade af medium tæthed). Det er et kompositprodukt, der fremstilles ved at findele løvtræ til træfibre, som kombineres med voks og harpiks som bindemiddel, hvorefter materialet formes til plader under tryk og høj varme.

Vi anvender udelukkende FSC-certificeret træ til vores MDF-produkter for at opnå vores ønsker i forhold til bæredygtighed.

Glas

Hovedbestanddelen af glas er sand, der er blevet renset for urenheder og blandet med andre mineraler, herunder silica, samt rester fra tidligere produktioner.

Vores glasproducent er placeret i Portugal og bruger høj kvalitetssand, der kommer fra nære kyster og de omkringliggende floder.

Klart glas er fuldt genanvendeligt i et internt kredsløb på fabrikken. Defekt eller overskydende klart glas opvarmes igen og genbruges i produktionen. Dette sikrer et lukket system af høj kvalitet, hvor glas ikke blandes med materialer fra eksterne kilder.