Free Deliveries to all European Countries

|

5 years warranty

|

FSC®-certified

Free Deliveries to all European Countries

5 years warranty

FSC®-certified

We have been pursuing sustainability since the day we founded Form & Refine. Sustainable business practices have shaped our company culture and a sustainable ethos influences everything we do. We believe that by using sustainable business methods we can preserve and even improve our environment by supporting cultures and individuals that rely upon sustainable craft. We do this for a more sustainable future.

We are committed to continuing to improve our own awareness, and that of our workforce and partners, so as to become fully conscious of the impact of our actions on the natural world. For us, making the world a better place is a way of life.

We are always seeking to learn from and improve upon our past experience and approach sustainability from new and exciting perspectives. We strive for sustainable development.

Form & Refine is an FSC®-certified company. The FSC (Forest Stewardship Council) is an international non-governmental organization dedicated to promoting responsible management of the world’s forests. We strive to use only FSC®-certified timber in our collection. As we mainly offer contemporary wooden furniture created with an environmentally conscious design philosophy, partnering with the FSC®is a natural choice.

This commitment to sustainability is aligned with the UN Global Goals (UNGG) on Sustainability. The UNGGs describe a broad range of global issues and objectives which correspond to the values of our own business. We have divided our sustainability commitment into the following 5 areas: CO2 Footprint, Durability, Social Equity, Economic Benefits and Natural Materials. You can dive into our 5 sustainability commitments below.

Our sustainability strategy commits us to minimizing our CO2 footprint by sourcing local materials and making use of local workshops. One of our sustainability goals is to have the sourcing and processing of materials all take place within a radius of 100 km.

We produce our furniture and wooden accessories in Europe only. We do not source timber from any location which is not in close proximity to our workshops. For that reason, we neither work with Teak or Mango Wood from South America and Asia nor with Oak from North America. This decision helps us minimize our CO2 impact immensely.

In addition, we use ships or trucks as means of transporting our materials and avoid air transportation.

Our goal

Our goal is that the maximum radius for the sourcing and processing of our materials never exceed 100 km.

We aim to make products made to last in terms of both ecological quality and timeless design. We believe this gives us a competitive advantage.

We pride ourselves on our practice of slow living, producing small batches of quality products each year instead of focusing on quantity and bringing out new products as often as possible. The culture we are developing represents the complete opposite of ‘the throwaway society’. “Slow living” is an integrated part of our business model, because this is required in order to be a sustainable business with focus on high quality natural resources.

– We do not follow fashion and trends.

– We create items to last a lifetime and be enjoyed for generations to come.

– We strive to create products that can become classics of design.

Guarantee

– We have a 5-year-guarantee on our entire collection. We believe this is mandatory in order to be a successful business with our focal point of sustainability.

– We make products that last in terms of both ecological quality and timeless design.

Claim rate and returns rate

– Our claim rate is 0.7 %. A rate which compares more favorably than most in the interior industry.

– A low claim rate means a much smaller impact on the environment as it reduces the number of items needing produced.

– Our return rate is 0.2 %. We have only had 14 returns in the entire last year. It is hugely satisfying for us that end-users of our products are pleased with the design of our products and the quality of our materials and this indicates that we are a successful business.

Our sustainability commitment includes social impacts of manufacturing that are often forgotten. We prioritize practices which produce social equity and speak to the ethical aspects of sustainability, specifically we work to preserve the rights of indigenous communities and keep ancient craftsmanship alive. We take employee welfare and human rights matters very seriously. This is mandatory for our sustainability commitment.

We work with social workshops, cooperatives and smaller family owned workshops with a tradition of craftsmanship.

This is who we work with and why:

– All of our alpaca material comes from a co-operative of 400 local farmers in the Andes region of Bolivia. This region is the natural habitat of the alpaca which form an integral part of the life of the native people. The family owned sewing workshop that is our main partner uses traditional craft techniques to process the luxurious fibres from these gentle animals into textile. Textile production is the main source of income of the native population and we are proud to have these family-owned workshops as our business partners. This is also our way of helping emerging markets or emerging economies in the world.

– All Shoemaker ChairsTM come from one of the last and oldest wood turners in Denmark which is family owned and run. We are working on promoting the craft and livelihood.

– All ceramic items come from a local pottery in Portugal which dates back to the 19th century.

– All glass items come from a local family-owned factory inPortugal, which is one of the last remaining producers of hand-crafted glass in the country.

– All A Line items come from a family owned joinery in the mountain town of Jajce in middle Bosnia Hercegovina.

– We work with HKI (Hans Knudsen Institute), a social workshop based in Copenhagen. HKI is an institution that helps people who, for different reasons, have difficulties in being a part of the Danish job market.

– We work with of the last remaining glass producer of the traditional Portuguese mouth-blow techniques. We work for honoring the old techniques and the craft created.

Goals:

– We want to continue working with more socially minded workshops and explore new ways of creating a sustainable social impact.

We aim to make a successful and profitable sustainable business without damaging our earth in the process. With this ambition, we aim to use our brand to make a positive difference by promoting our sustainability commitment agenda.

We want our products to be chosen over less sustainable items. To put it simply:

We hope to make an impact so great that consumers see products like ours as necessary for the protection of the natural world. We believe that we can achieve this by providing high quality sustainable products at competitive prices.

Natural materials have a much smaller impact with regard to CO2 emissions when compared to other materials.

We use only the most durable and sustainable materials like wood, brass, stoneware, steel, alpaca, cork and raw vegetable tanned leather. Many of these materials patinate beautifully over time and ensure a product which will stand the test of time.

What we don’t do or use

We do not use any aluminium

Aluminium has a wide range of harmful environmental impacts and requires large amounts of energy to produce. The amount of energy needed to produce aluminium is 211 GJ per tonne, compared to 22.7 GJ per tonne for steel or brass. That means steel causes 90 % less energy consumption than aluminium. This is one of many reasons why we only use steel or brass.

We would, however, like to use 100 % recycled aluminium when the opportunity arises.

We do not use conventional plastic in our products, only rPET (recycled PET)

We do not use conventional plastic in our furniture, because plastic comes from fossil fuel production, much of it from fracking, which is a devastatingly process for the environment. PET is one of the few types of plastic that can be recycled, because it is made of a limited number of simple ingredients and contains no toxins. This recycled material is called rPET, which stands for ‘recycled PET’. We use rPET in our products when its properties make sense and are difficult to replace by other materials, such as parts of our packaging and as stuffing for our inner cushions.

We do not use any chemicals and toxins

Chemicals and toxic waste can harm people, animals and our environment in many different ways, whether it ends up in the ground, in streams, or in the air. Some toxins, like mercury and lead, persist in the environment for many years and accumulate over time.

Packaging

We mainly use recycled cardboard in our packaging, either ordinary recycled cardboard or recycled honeycomb cardboard.

We aim to use only paper tape, and we use protective filling made of shredded recycled cardboard.

It is our goal to avoid plastic in our packaging and, when necessary, only to use rPET. This is a difficult challenge since we need to find local solutions to the problem. For instance, it does not make much sense to transport a good sustainable packaging solution from Europe to Bolivia because of the environmental impact of the transport. It is our goal only to use rPET in our packaging; an ambition we have already accomplished for our product collection. This is necessary for us in order to reach our sustainability commitment.

Our Goals

– We aim to use only rPET or plastic free packaging by 2025.

– We want all our wood items (including packaging) to come from certified wood sources by 2024.

– We aim to use more upcycling or recycled materials when possible.

Explore the materials we use:

Wood

Form & Refine’s heart and soul is high-quality wood as it is undoubtedly one of the most sustainable materials in the world and will has less impact on the environment compared to all other materials.

Wood is a naturally renewable material. It lasts a long time, it can be recycled and reused, it absorbs carbon dioxide, it is great at retaining heat, its waste is 100 % biodegradable and it has a positive effect on your physical and mental health.

Most of our wood comes from certified forests, either FSC (Forest Stewardship Council). The wood for the Shoemaker production is PEFC-certified (Programme for the Endorsement of Forest Certification).This reflects our commitment to helping to prevent deforestation, preserve biodiversity and protect human rights.

We would like to emphasize that we only use sourced wood from Europe with our main workshops being close to the source.

Our goal:

– We aim to source all the timber for our wooden furniture from certified forests by 2025.

Alpaca

Alpaca fibers are ecologically friendly and keep their natural character during processing. Our Alpaca wool is never exposed to any chemicals or toxins. The Form & Refine Aymara Alpaca collection is made of 100 % pure alpaca fiber and not combined with synthetic or other low quality materials.

We almost solely use natural colouring of the alpaca breed and add only a few colour products to the yarns, using eco-friendly dyestuffs which are approved for garment manufacture.

Cork

All our cork comes from Portugal. Cork is a natural, environmentally friendly material. It biodegrades completely and can be easily recycled without producing any toxic residues.

The cork bark is harvested from the tree every 9 to 12 years. Each time cork is harvested, the cork bark regenerates and in doing so absorbs CO2. Cork oak trees in Portugal alone help offset 10 million tons of carbon every year. They are also important producers of oxygen.

Cork and cork oak woodlands are a vital source of regional rural employment and guarantee the survival of local communities.

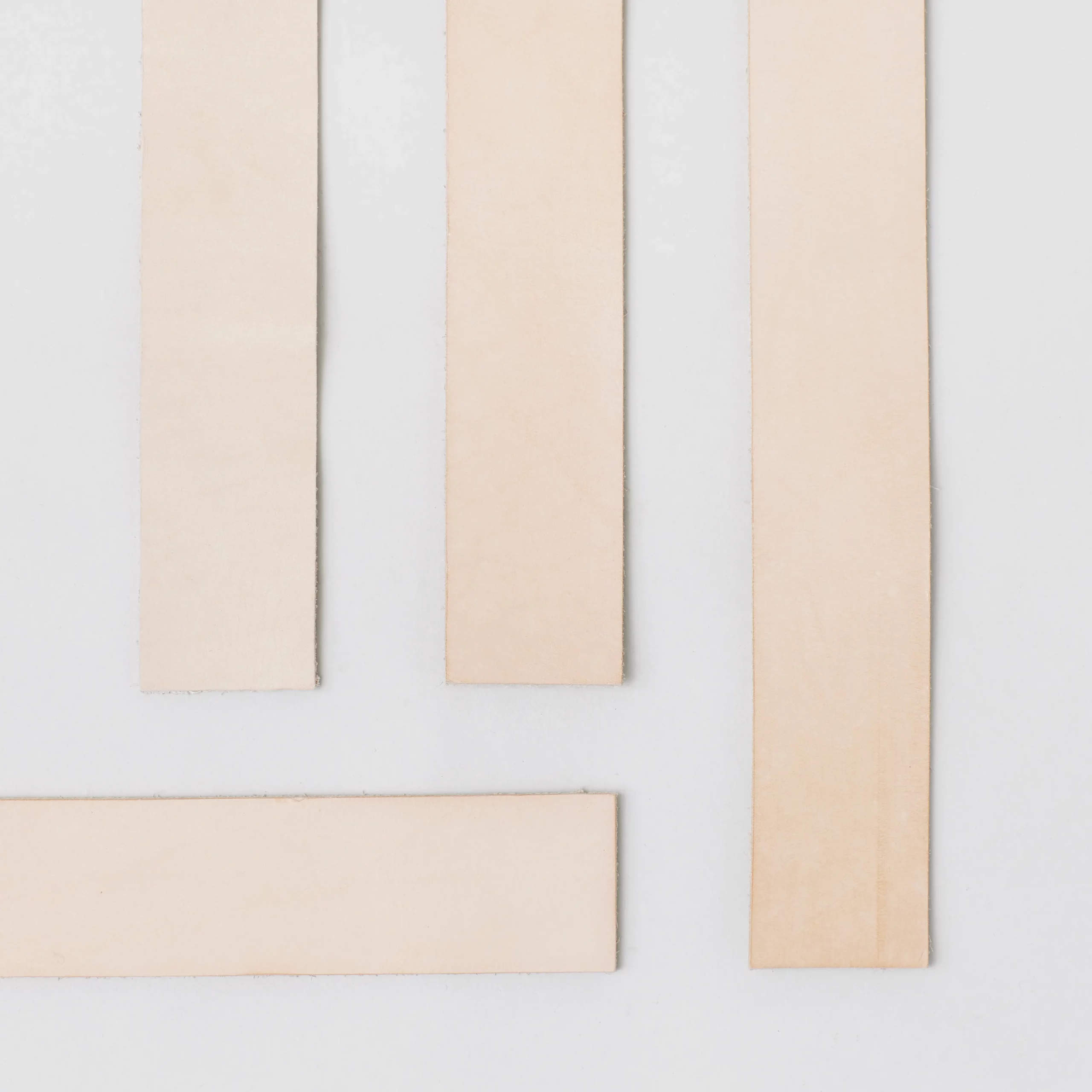

Vegetable tanned leather

Our raw leather is made from cow skin in Italy and Portugal. Vegetable tanning is a traditional method of tanning leather with a rich history dating back to approximately 6.000 BCE. Vegetable tanning is an organic method which relies upon natural vegetable tannins from bark or other plant tissues.

Due to the careful tanning process and the natural tannins, vegetable tanned leather develops a rich and beautiful patina over time. It does not crack or dry out. It is thick and hard wearing and thus has a very long lifespan. It has an earthy and natural tone and scent. All our raw vegetable tanned leather is biodegradable.

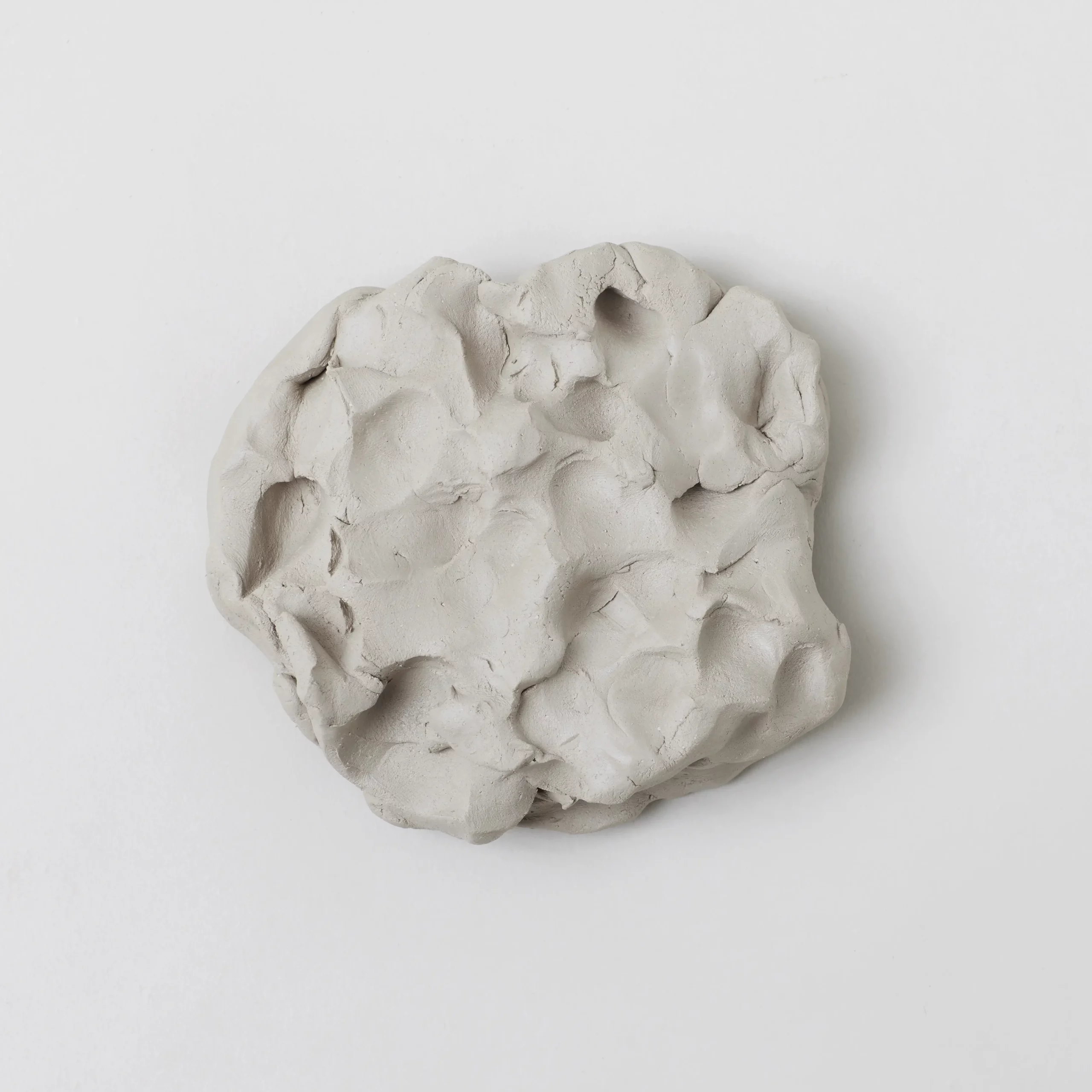

Stoneware

Our stoneware is made from Portuguese clay which is a natural, malleable material composed of minerals and water. Natural mineral clay is found naturally in the earth and is an excellent resource for creating beautiful, safe and sustainable items.

Stoneware is dense pottery fired at high temperatures to make it resistant to liquids or non-porous. It is made from clay and is more durable than other kinds of pottery and earthenware.

High-quality stoneware is completely non-toxic, food-safe, lead-free and can last forever if cared for.

Recycled waste

Recycled waste holds immense potential for sustainable innovation. An example is Recoma’s Pack Wall Design Board, made from discarded juice and milk cartons blended into a composite of cardboard, plastic, and aluminum. Fully recyclable, the material requires no separation during disposal, as it can be melted down and reused—supporting a circular production process.

Each year, this approach recirculates 7 million kilograms of Nordic packaging waste, preventing nearly 5,000 tons of CO₂ emissions. The process uses no chemicals, additives, or deforestation—just discarded cartons and energy. It’s more than a material; it’s a sustainable solution turning waste into value.

A notable application of this material is Form & Refine’s Remake Stool, showcasing how innovative design and sustainability intersect.

Duck Down for Inner Cushions

Our inner cushions consist of 50 % fiber ball and 50 % duck down. The fiber ball consists of 100 % recycled PET bottles.

The duck down comes is sourced from a traditional poultry farm in Hungary. We do not use duck down from living animals. The duck down is washed, dried and completely sterile.

Glass

The main ingredient of glass is sand that has been cleansed of iron salt impurities and mixed with other minerals, including silica, as well as off-cuts or scraps from previous productions.

Our glass manufacturer is located in Portugal and uses high-quality sand sourced near the natural coastline and surrounding rivers.

Clear glass is fully recyclable in the internal circuit at the factory. All excess clear glass from off-cuts or rejects is reheated and reusedin the production. This ensures a closed system of high-quality glass that is not mixed with glass from outside sources.